The product is as shown in the picture. The material is LDPE, the shrinkage rate is 1.02, and the average wall thickness is 1.0 code. The top of the product is designed with a disposable pull ring, and the outside is designed with a thread. This thread is matched with the outer cap of the soy sauce bottle to fit tightly without loosening.

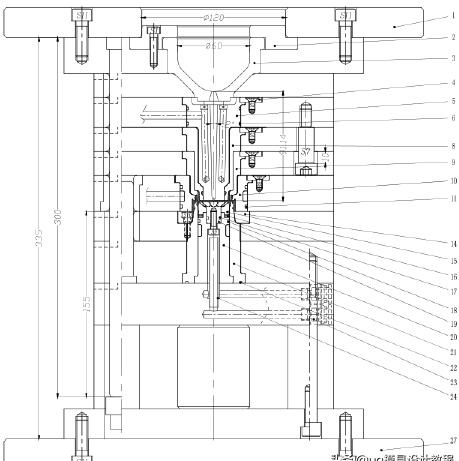

Mold design

One: The template needs to be subdivided multiple times. The processing accuracy of the template is very important. The processing concentric of the cavity hole position shall not exceed 0.015, and the hole diameter tolerance shall be 0.015. The circular hole position of the template is processed by a high-precision coordinate boring machine to ensure the size of the hole. Tolerance and geometric tolerance.

Two: Soy sauce bottle cap mold, the external thread and disposable pull ring are designed in the fixed mold, opened separately in order to achieve strong release. The inverted buckle on the edge of the inner diameter is pushed out by the push plate.

Three: Point the gate at the top of the product to enter the glue.

Four: The cooling circuit is designed inside the insert to realize product cooling. The quality of the selected sealing ring should be good, and the details such as steps should be done in the design and processing of the insert.